In demanding industrial environments—such as petrochemical plants, power generation units, and high-temperature pipelines—equipment reliability is not just important, it is essential. Triple eccentric butterfly valves have become one of the most trusted solutions for high-temperature and high-pressure systems, offering superior sealing performance, long service life, and enhanced operational safety.

As a high-value product with strong buyer intent and relatively low competition, triple eccentric butterfly valves are increasingly in demand across global industries.

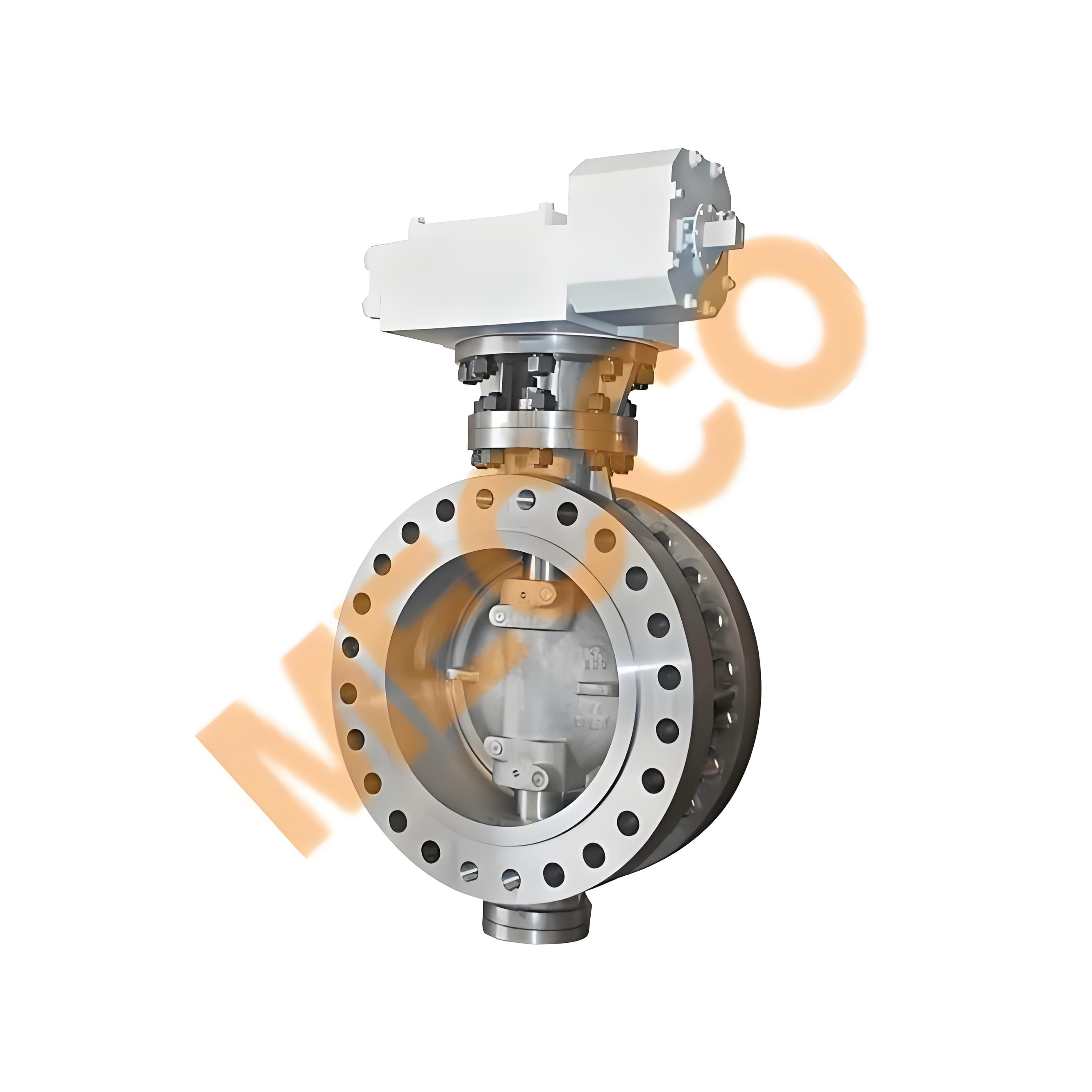

Triple eccentric butterfly valves (also called eccentric butterfly valves) are engineered with three offsets:

This triple-offset design ensures that the valve disc never rubs against the valve seat during operation. Instead, it engages the seat in a friction-free, cam-like motion, minimizing wear and preserving sealing integrity even under extreme working conditions.

Because the sealing pair is metal seated, these valves can withstand high temperature, high pressure, and corrosive or abrasive media far better than traditional soft-seated designs.

Triple eccentric valves utilize metal seated valves technology, where both the disc and sealing surface are made of hardened, temperature-resistant materials.

This allows:

Most triple eccentric butterfly valves are manufactured according to API 609, ensuring high performance, quality consistency, and global acceptability. API 609 certification strengthens reliability, especially for critical applications in the oil & gas, refinery, and power sectors.

The frictionless closing motion reduces seat wear, maintaining a bubble-tight seal even after long-term use. This is essential for preventing leakage in high-temperature and high-pressure systems where safety risks are elevated.

The conical sealing surface, combined with precision metal overlays such as Stellite, ensures exceptional:

This makes triple eccentric valves ideal for steam lines, thermal oil systems, gas turbines, and high-temperature petrochemical pipelines.

Triple eccentric butterfly valves fall into a category of high-value industrial valves with significant profit margins and high global purchasing intent. Buyers searching for this category typically include engineers, procurement teams, and industrial project managers—people who already know what they need and are ready to submit inquiries.

Key advantages from a market perspective:

For companies targeting international B2B lead generation, this product class offers excellent SEO opportunities.

Triple eccentric butterfly valves are widely used in:

The valves’ durability and reliability make them an indispensable component in critical infrastructure.

It is a high-performance butterfly valve with three engineered offsets that prevent friction between the disc and the valve seat, offering excellent sealing and durability.

Yes. The metal seated design and conical sealing surface make them highly resistant to high temperature, often above 500°C.

Most are designed according to API 609, which governs performance requirements for butterfly valves in industrial applications.

Oil & gas, power generation, petrochemical, metallurgy, shipbuilding, and any system involving high-temperature or high-pressure fluids.

Their friction-free closing, strong sealing surface, and ability to withstand extreme conditions eliminate leakage risks and reduce failure rates in critical pipelines.

Because manufacturing requires advanced machining and engineering capabilities, fewer suppliers exist, and global buyers show strong intent for these specialized valves.