How to Choose the Right Industrial Valve for Oil & Gas Applications

Learn how to choose industrial valves for oil & gas applications based on pressure, temperature, and media. Covers ball, gate, globe, check, and API 6D valves with expert guidance from Mecco.

Selecting the correct industrial valve is essential for ensuring safety, efficiency, and reliability in the oil and gas industry. Valves are designed to regulate the flow, isolate equipment, and manage liquids and gases under a wide range of operating conditions. Choosing the wrong valve can lead to leakage, system failure, and costly downtime. This industrial valve selection guide explains how to choose the optimal valve type—such as gate valves, ball valves, globe valves, check valves, and butterfly valves—based on pressure, temperature, medium characteristics, and working conditions. We also reference Mecco’s professional strength, including API and CE certifications, to enhance trust and E-E-A-T.

1. Key Considerations When Choosing Industrial Valves

1.1 Pressure Conditions

Pressure is one of the most important variables in oil and gas applications.

- High pressure valves are required in upstream and midstream operations, where burst risk and sealing integrity are critical.

- Standards such as API 6D valves ensure reliable pressure management in pipelines transporting crude oil, natural gas, and refined products.

- Valves must remain safe during surges, transient pressure spikes, and emergency shutdowns.

Valve recommendation by pressure:

- Ball valves – Excellent for high-pressure applications due to tight sealing and quick operation.

- Gate valves – Ideal for fully open or fully closed service in high-pressure pipelines.

- Check valves – Prevent reverse flow and protect compressors/pumps under high pressure.

Mecco’s product portfolio includes high-pressure API 6D-certified valves designed for stable operation under demanding pipeline conditions.

1.2 Temperature Conditions

Oil and gas production often involves extremely high or low temperatures:

- High-temperature valves are used in refining, cracking, and steam systems.

- Cryogenic valves (low-temperature valves) are essential for LNG, nitrogen, hydrogen, and other low-temperature media.

Valve recommendation by temperature:

- Cryogenic ball valves and cryogenic globe valves – Designed to prevent seat shrinkage and leakage at temperatures as low as −196°C.

- High-temperature gate valves – Used in thermal cracking and furnace-related service.

- Butterfly valves – Suitable for medium-temperature ranges, especially in large-diameter pipelines.

Mecco provides a full series of cryogenic valves tested under cryogenic, high-temperature, and high-pressure conditions, supported by CE, API, TS, and SIL certifications.

1.3 Medium Characteristics (Liquids, Gases, and Special Media)

Different media—liquid hydrocarbons, gases, corrosive fluids, and slurries—require different valve materials and structures.

For liquids (including crude oil):

- Gate valves or ball valves are ideal for fully open flow with low pressure loss.

- Material selection must consider sulfur content, wax components, and corrosion.

For gases:

- Ball valves and butterfly valves offer better sealing against gas leakage.

- Check valves prevent dangerous reverse flow during compressor shutdown.

For corrosive or special media:

- Special alloys, hard-facing, and jacketed designs may be required.

- Globe valves provide accurate flow control for corrosive additives or chemicals.

Mecco offers special alloy valves, hydrogenation valves, oxygen valves, and abrasion-resistant valves for complex media handling.

1.4 Working Conditions and Operation Requirements

Operating conditions include flow rate, shutoff frequency, installation dimensions, and maintenance convenience.

Shutoff applications

- Ball valves – Provide reliable tight sealing with quick quarter-turn operation.

- Gate valves – Best for rare operation cycles where the valve stays fully open most of the time.

Flow control applications

- Globe valves – Precise flow rate adjustment.

- Butterfly valves – Good for throttling in low/medium pressure systems.

Backflow prevention

- Check valves – Essential in pump discharge lines to avoid reverse flow and system damage.

Because valves are designed for different mechanical functions, correct selection avoids leakage, vibration, and cavitation.

2. Choosing the Right Valve Type for Oil & Gas Applications

2.1 Gate Valves

- Primarily used for on/off control.

- Suitable for crude oil, water injection, and pipeline isolation.

- Low pressure drop, ideal for long-distance transport.

- In oil and gas, they are widely adopted due to their reliability when fully open.

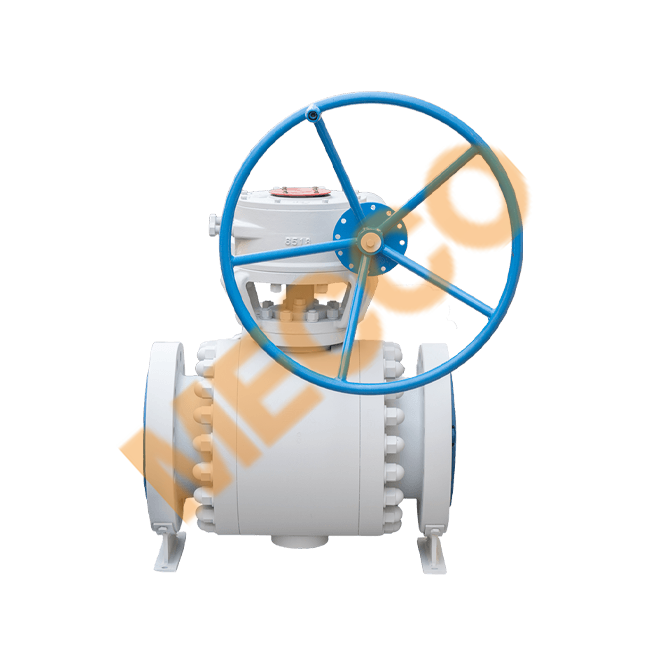

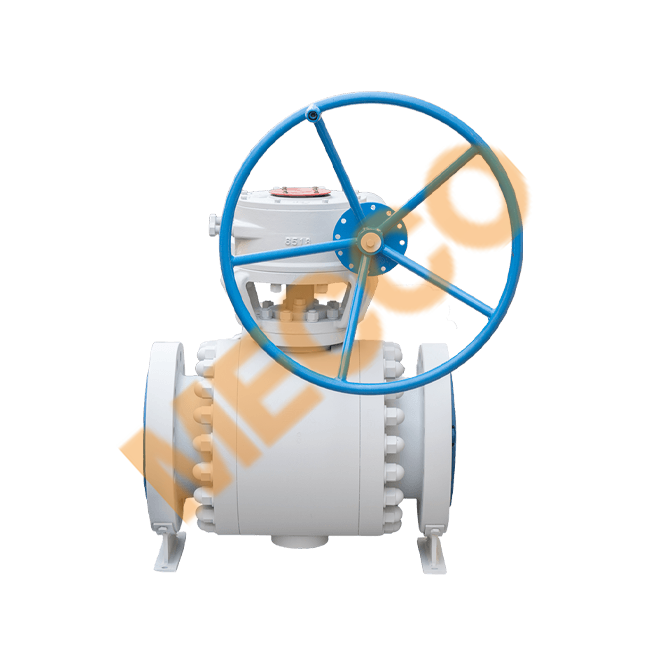

- Provide tight sealing, fast operation, and durability.

- A top choice for high pressure valves and gas pipelines.

- Trunnion ball valves handle larger sizes and higher pressures.

- Floating ball valves suit mid-pressure systems.

2.3 Globe Valves

- The best choice for flow control and precise flow rate regulation.

- Suitable for chemical dosing, steam lines, and pressure management.

2.4 Butterfly Valves

- Lightweight and cost-effective for large-diameter pipes.

- Suitable for liquids and gases at low to medium pressures.

2.5 Check Valves

- Essential for preventing backflow in pump, compressor, and pipeline systems.

- Protect equipment from damage caused by sudden flow reversal.

3. Why Choose Mecco Valves for Oil & Gas Applications?

Mecco is an experienced global manufacturer with:

- API 6D, CE, DNV ISO9001, TS, and SIL certifications

- More than 50 patents and participation in over 30 national/industry standards

- Production capacity of 43,500 tons of valves annually

- Complete product lines covering gate, ball, globe, butterfly, check, cryogenic, and special alloy valves

Mecco performs testing under high-pressure, high-temperature, and cryogenic conditions, ensuring product safety and reliability for oil & gas service.

4. FAQs: Choosing Industrial Valves for Oil & Gas

Q1: What is the most commonly used valve type in the oil and gas industry?

Gate valves and ball valves are the most widely used. Gate valves are ideal for pipeline isolation, while ball valves are preferred for high-pressure gas service.

Q2: What are API 6D valves?

API 6D valves meet the American Petroleum Institute’s rigorous requirements for pipeline valves, ensuring safety, tightness, and durability under high pressure.

Q3: How do I select a valve for high-pressure applications?

Choose high pressure valves such as trunnion-mounted ball valves or forged steel gate valves that meet API 6D standards.

Q4: Which valve offers the best flow control?

Globe valves provide the most accurate regulate the flow capability.

Q5: What valve prevents reverse flow?

A check valve automatically closes to stop reverse flow in pipelines.

Q6: How do cryogenic conditions affect valve selection?

Choose cryogenic valves with extended bonnets, special seats, and materials designed for extremely low temperatures.

Q7: Are butterfly valves suitable for oil and gas systems?

Yes, especially for large-diameter, low-pressure pipelines where space and cost efficiency are important.

Conclusion

Choosing the right industrial valve requires evaluating pressure, temperature, medium type, and working conditions. By understanding the characteristics of gate valves, ball valves, butterfly valves, globe valves, and check valves, engineers can ensure safe and efficient flow management. With strong technical capabilities and certifications including API 6D, CE, and ISO, Mecco provides reliable valve solutions for the global oil and gas industry.