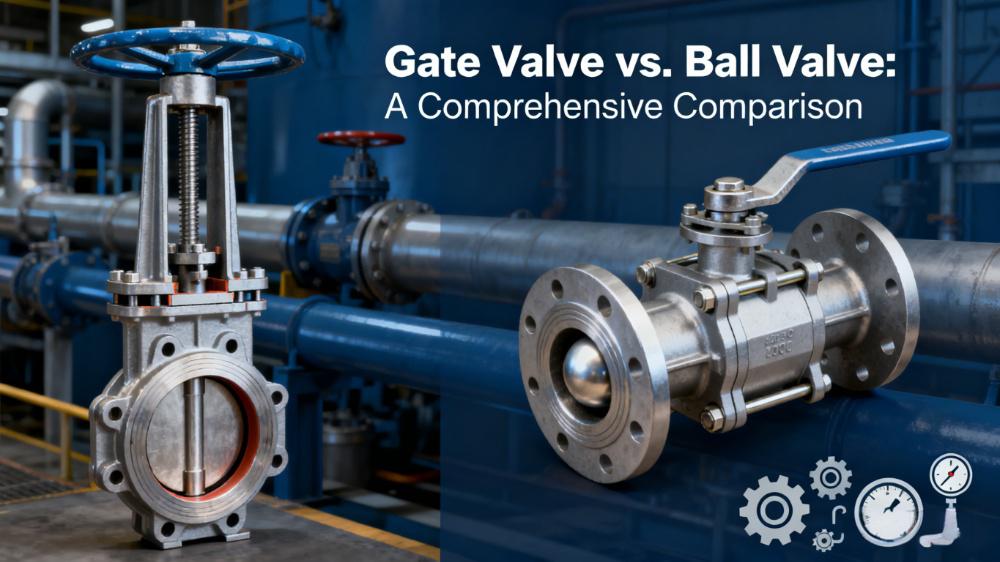

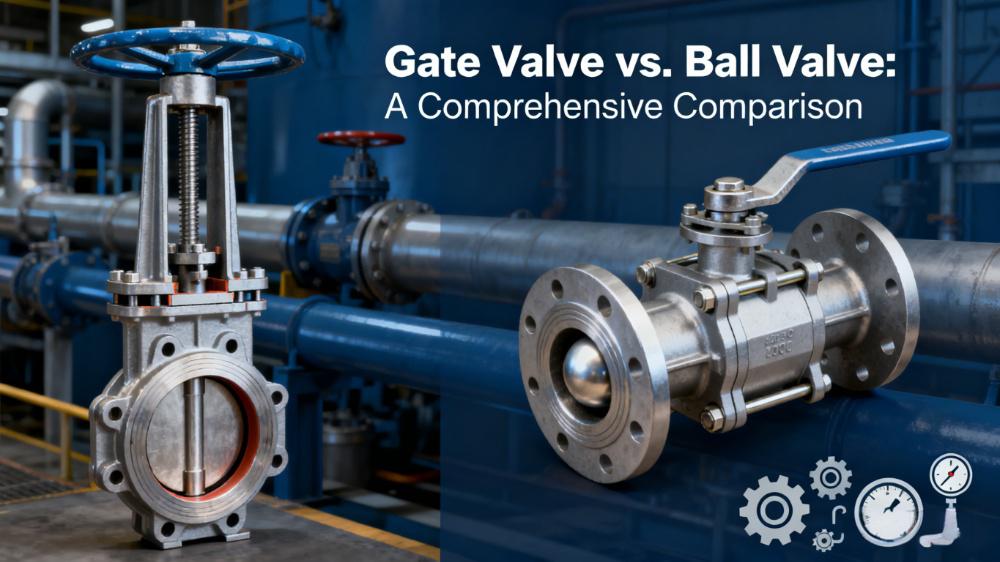

Gate Valve vs. Ball Valve: Key Differences, Applications, Pros & Cons

Compare gate valves and ball valves in working principles, flow control, high-pressure use, advantages, and applications. Learn which valve type fits your system.

Selecting the right industrial valve is essential for safety, efficiency, and long-term performance. Among all valve types, gate valves and ball valves are the most widely used in pipelines, power systems, chemical plants, and large water supply lines. Although both valves open or close the flow, their structures, mechanisms, and applications differ significantly.

This guide offers a comprehensive comparison of gate valve vs. ball valve, covering working principles, design differences, high pressure applications, flow control performance, installation space requirements, and much more.

A gate valve is a linear-motion valve designed for on/off control rather than throttling.

Gate Valve Working Principle

The valve uses a gate (wedge or disc) that moves vertically inside the valve body. When the gate lifts, the valve is fully open; when lowered, it is tightly sealed to close the valve.

Gate valves are generally used where the valve remains open for long periods and only occasionally cycles.

Key Characteristics

- Minimal pressure loss when fully open

- Not suitable for flow regulation

- Large installation space required due to stem movement

- Smooth operation reduces risk of water hammer

Typical Applications

- Municipal water systems

- Large water supply lines

- Power plants (steam, condensate, cooling water)

- Oil & gas transport lines

- High-temperature flow environments

A ball valve uses a spherical ball inside the valve body, with a hole that aligns with the pipeline to allow flow.

Quarter-Turn Operation

Ball valves operate with a quarter turn—only 90 degrees are needed to go from fully open to fully closed. This makes them ideal for fast shutoff systems.

Ball Valve Application

Ball valves are used in:

- Petrochemical and chemical process lines

- High pressure applications

- Automated control systems

- Residential and industrial water systems

- Gas pipelines

Multi-Port Configurations

Modern process systems often require multi port configurations (3-way, 4-way). Ball valves support these designs, allowing:

- Flow diversion

- Mixing

- Flow redirection

This versatility is not available with standard gate valves.

3. Gate Valve vs. Ball Valve: Key Differences

Below is a structured comparison of the two valve types:

Operating Mechanism

- Gate Valve: Multi-turn mechanism; stem moves gate up/down to open or close.

- Ball Valve: Quarter turn operation, rotating the ball 90 degrees.

Flow Control & Flow Regulation

- Gate Valve: Poor for flow regulation; throttling erodes the gate.

- Ball Valve: Good for flow control, especially V-port designs.

Pressure & Temperature

- Both can handle high temperatures.

- Ball valves usually outperform gate valves in high pressure applications.

Installation Space

- Gate Valve: Needs larger vertical space.

- Ball Valve: Compact footprint; ideal for tight installations.

Water Hammer

- Gate Valve: Lower risk because closing is slow.

- Ball Valve: Higher risk if closed too quickly due to rapid torque.

Sealing Performance

- Ball valves typically offer tighter shutoff.

- Gate valves provide excellent full-bore flow when fully open.

4. Pros & Cons Overview

Gate Valve Pros

- Excellent full-bore flow

- Low pressure loss

- Suitable for high-temperature & large pipe diameters

- Lower risk of water hammer

Gate Valve Cons

- Not for throttling

- Slower operation

- Requires more installation space

- More moving parts

Ball Valve Pros

- Fast 90-degree operation

- Compact design

- Strong shutoff capability

- Supports multi port configurations

- Good for flow control

Ball Valve Cons

- Quick closing may cause water hammer

- More expensive in very large sizes

- Not ideal for abrasive media in partially open positions

5. Applications by Industry

Gate Valves

Common in:

- Power plants (steam isolation, cooling water lines)

- Water distribution networks

- Oil & gas pipelines

- Mining and mineral processing

- Fire protection systems

Ball Valves

Common in:

- Chemical processing

- Natural gas distribution

- Industrial automation

- Food & beverage systems

- High-pressure hydraulic systems

6. Which Valve Should You Choose?

Choose a gate valve if your system needs:

- Slow, controlled operation

- Minimal pressure drop

- Reliable full open/full close function

- Larger pipeline diameter support

Choose a ball valve if your system needs:

- Fast action (quarter-turn)

- Tight shutoff

- Flow regulation capability

- Compact installation

- High-pressure handling

- Multi-port flow routing

7. Frequently Asked Questions (FAQ)

1. Which is better, a gate valve or a ball valve?

Neither is universally better. Gate valves are better for large pipelines and high-temperature service; ball valves excel in fast-acting shutoff and high-pressure systems.

2. Can a ball valve be used for flow regulation?

Yes. Ball valves offer better flow control than gate valves, especially in V-port designs.

3. Why do ball valves cause water hammer?

Their rapid quarter-turn operation can suddenly stop flow, creating a surge.

4. Are gate valves suitable for high pressure applications?

Yes, but ball valves often perform better under extreme pressure.

5. Which valve needs more installation space?

Gate valves, due to their rising or non-rising stem structure.

6. What are multi port configurations in ball valves?

These are 3-way or 4-way ball valves that redirect or mix flow—common in chemical processing and automation.

7. Are gate valves good for throttling?

No. Throttling a gate valve damages the gate and reduces sealing performance.

8. Do both valve types reach fully open or fully closed positions?

Yes. Both can be fully open or fully closed, but ball valves achieve it faster with a 90-degree turn.

9. Which valve type is used in power plants?

Gate valves are common for steam isolation; ball valves are used in control, chemical feed, and auxiliary systems.

Conclusion

Understanding the detailed differences in gate valve vs. ball valve performance helps engineers and procurement teams make informed decisions. Gate valves excel in large-scale, high-temperature, full-open/full-close service, while ball valves offer versatile flow regulation, compact size, and excellent sealing for high pressure applications.